Print Finishing Services

Qualprint offers a full range of in-house print finishing technologies that empower your designers to create print materials that perfectly reflect the brand you want to build. Of course, we’ve carefully evaluated available finishing technologies to bring you only the best of the best. Like our incredible Hybrid Finisher – a single machine that can do hot foil stamping, embossing, and die cutting. This lets us add higher-attraction finishing touches to our customers’ print jobs, and because we can do it all in-house, we’re better able to control quality, cost and turnaround times.

But first, for those of you who aren’t print experts, let’s take a moment to explain what our print finishing services are and how it can help shape your brand image.

Loosely defined print finishing is everything that happens after a piece has gone through the printing press. Some finishing options are used to beautify the finished piece. Others can be used to protect it and make it more durable. Others add functionality. And some do all three. We’ve outlined some of the most popular options below – all of which we offer and all of which can help you create a unique image for your brand:

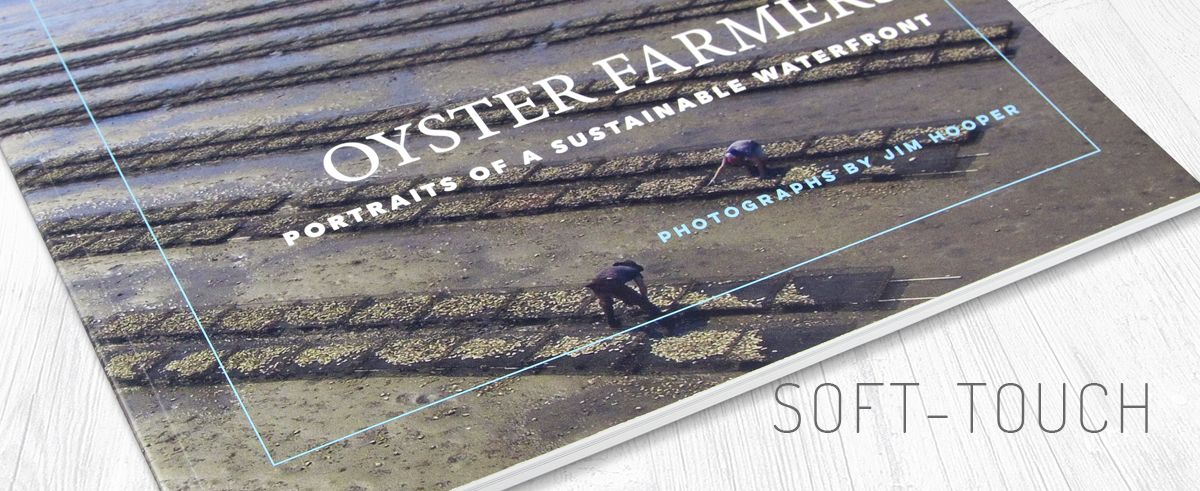

Special Print Coatings

Added after printing, print coating comes in many shapes and forms including UV and aqueous coatings. Depending on the goal, these can be used to add a glossy, satin or matte finish to a printed piece as well as an interesting tactile sensation – like one called “Soft Touch.” They can also make it more resistant to various types of damage like fingerprints, abrasion or yellowing over time.

Flood Varnish and Spot Varnish

Varnish is basically clear ink. Flood varnish means covering the entire piece to protect it and to give it high-gloss, satin or matte finish. Spot varnish is an effect that adds varnish only to specific areas of a printed piece – for instance to make a headline or image pop off the page – or to add texture.

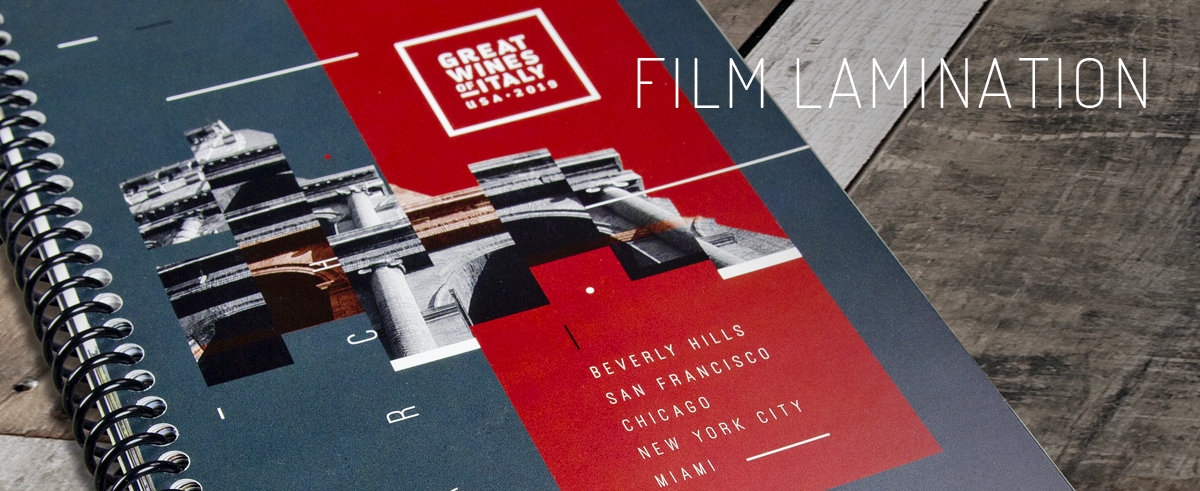

Film Lamination

Film lamination most commonly refers to sealing a printed piece between two sheets of film – to protect it and create eye-catching effects like different gloss levels and even textures like velvet or canvas

Die-Cutting Services

Our die-cutting service is the process in which your printed piece is cut with incredible accuracy to give it an unusual overall shape – or to remove specific bits – like cutting out your logo or adding a circular cutout to tease what’s on the next page.

Foil Stamping (Hot Foil Stamping)

Foil stamping is when heat is used to fuse foil onto a printed piece to highlight a specific area like your logo, adding shimmer, texture and a 3D effect. It’s one of the most powerful tools in a designer’s kit, giving a unique and sophisticated look to any printed piece and perfect for building a high end, luxury image for your brand.

Embossing Services

This finishing option creates a 3D textured effect by pressing an image or shape into your printed piece. This adds dimension to your pieces and can be used to call attention to a specific area like your logo – or to add a new element all its own like a seal or award emblem. Shapes can be very detailed and when combined with other effects like foil stamping, embossing they can create truly standout effects.

These don’t represent all your finishing options. We have more. But they do represent some of the most powerful tools your designers can use to transform a good printed piece into an exceptional one. Other more utilitarian and self-explanatory finishing capabilities we can offer you include folding, drilling, binding, collating and shrink wrapping.

To see some additional examples of our print finishing options in use, check out our fold out Qualprint business cards below. Each is die-cut and foil stamped with both UV and spot UV coatings. And our brand story is inside.